Get Lean with 2D Data Matrix Barcodes, Part 2

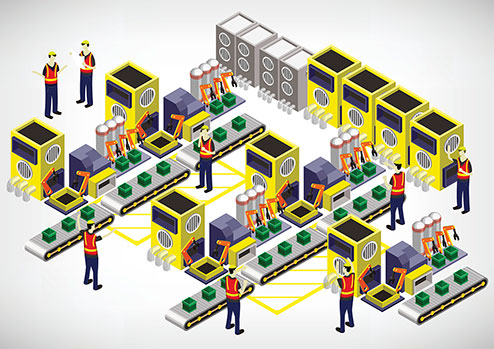

Welcome back to my series on how to Get LEAN by implementing 2D Matrix Barcodes in your manufacturing facility. In my last blog, I shared how the physical features of a 2D Data Matrix barcode that has been applied via Direct Part Mark (DPM) have been beneficial to manufacturers of Print Circuit Boards (PCBs) and …