Get Lean with 2D Data Matrix Barcodes, Part 3

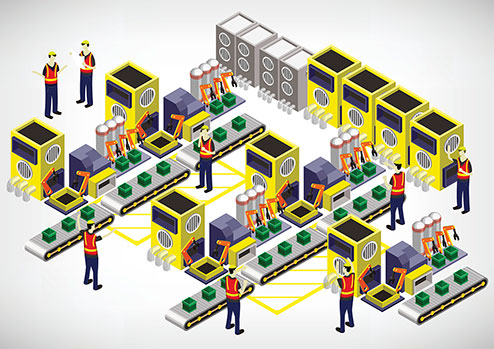

Thanks for stopping back in to read the 3rd part of this series on “Getting LEAN” with Data Matrix Barcodes in the manufacturing industry. If you missed the first two parts, you can read them here: Part 1 Part 2 Application Versatility Whether it be the assembly lines, final assembly lines, test and measurement locations, …