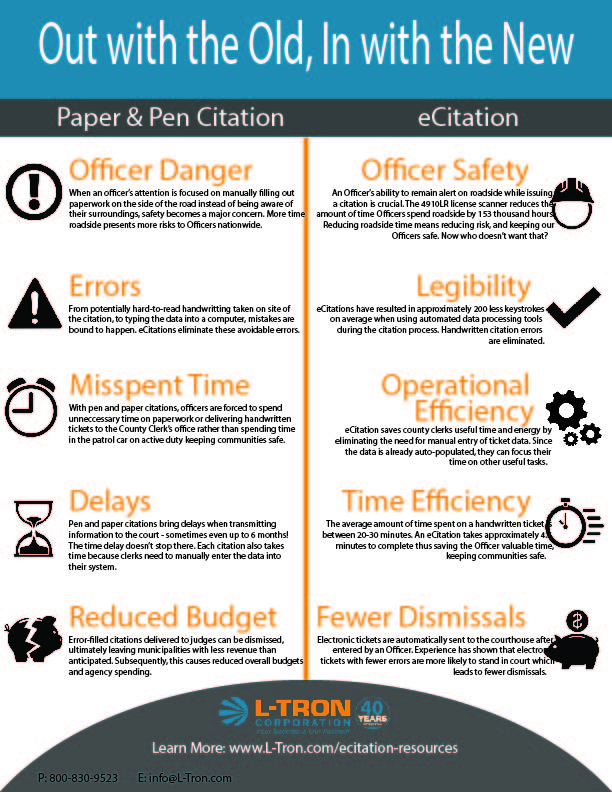

Out with the Old, In with the New

When was the last time you wrote a note to someone using pen and paper? Our guess would be that it has been a while. Don’t be mistaken, there is a place for it, not for traffic citations. We are seeing more and more agencies moving away from handwritten ticketing and adopting electronic citation as …